Canvas Stretcher

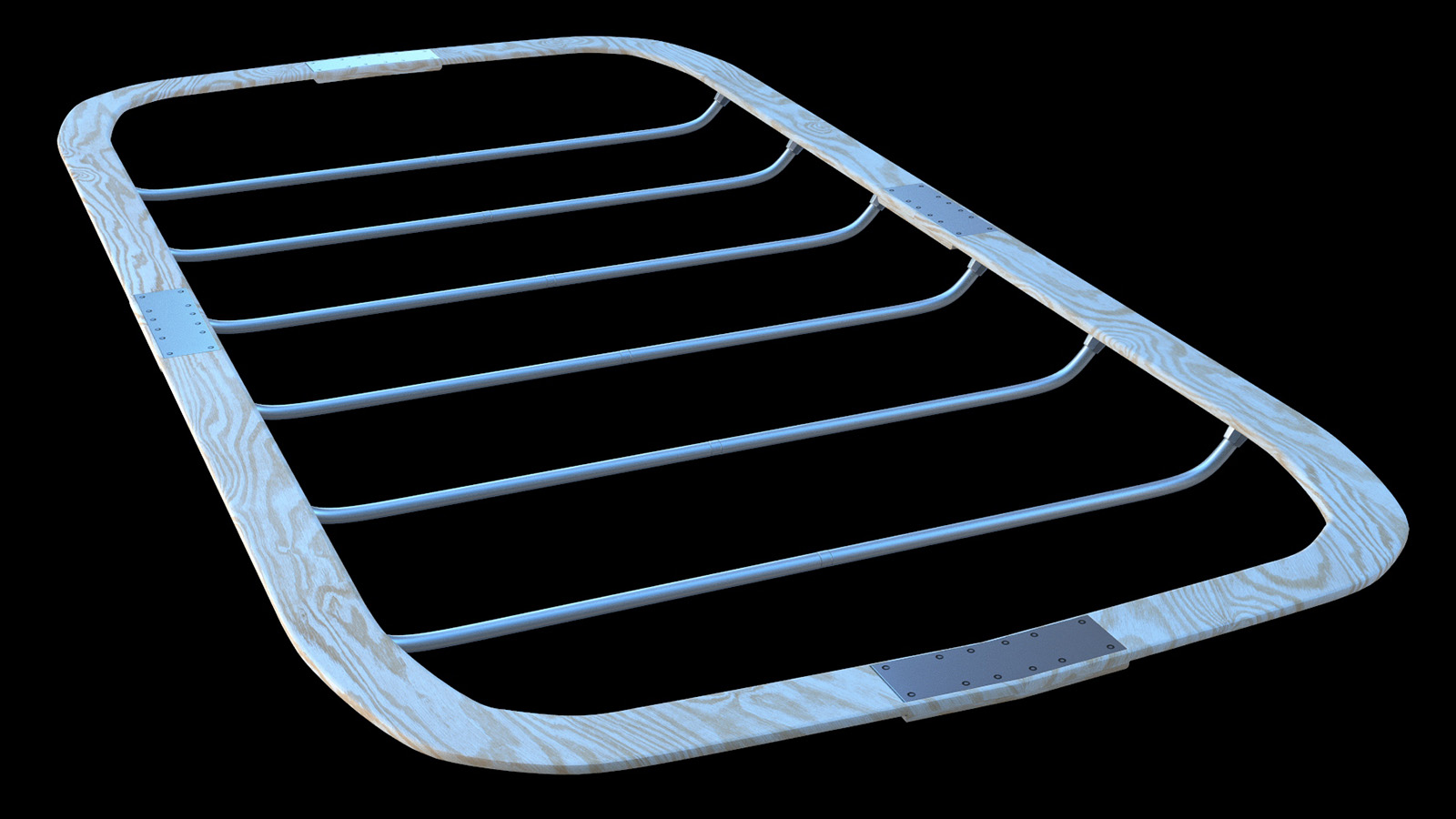

In order to move beyond the limitation of 4’ x 8’ pieces of Masonite, the largest size of manufactured sheet good, a continuous piece of canvas will be necessary. Shaun at Breezy Canvas has been advising me on the design. This new painting surface is less of a supporting table and more of a canvas stretcher, resisting compression.

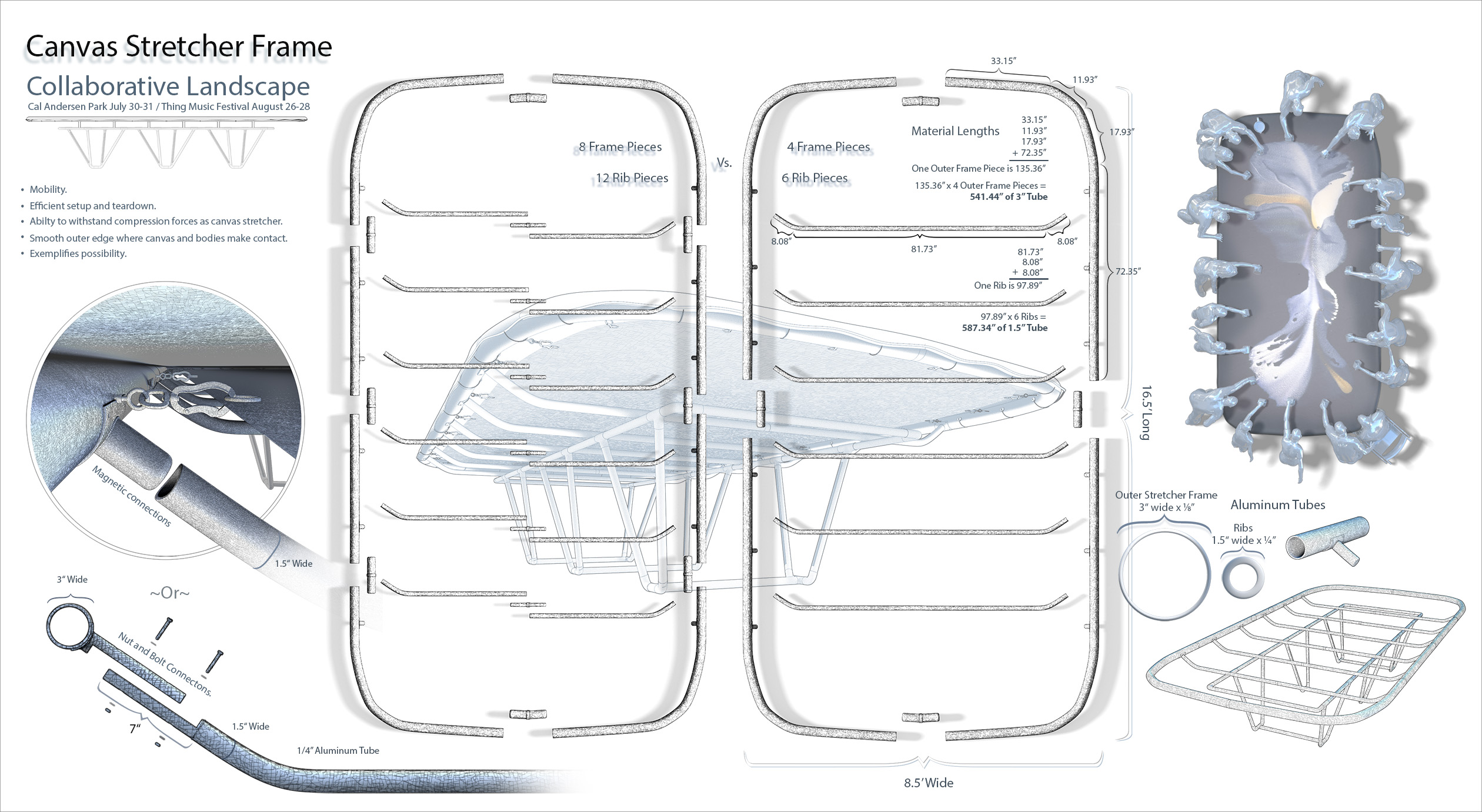

The second design of this canvas stretcher, at the bottom of the page, is the ideal design made entirely of aluminum. It will have the ability to disassemble into component pieces that could be shipped in road cases. This would enable our group to travel to distant opportunities and residencies. I have been working on this design for the past ten years and in the past two, have made a 3-D animation of its assembly, in the video below. As we present these upcoming painting events, I will be working towards making this more mobile painting table.

I have prepared this aluminum design with a fabricator who could help me to build it if one of two grants come through in the next month. While my latest applications are the best I have presented, I cannot count on them with the time left before the event in the park. I have an alternate design.

In these last two weeks of June, I am looking to connect with a woodworker who could help me cut and assemble the simpler design above, from four pieces of plywood. If you know of anyone who might be interested, please help us to connect. I will begin cutting these shapes and be preparing the four pieces in my small studio but having access to a slightly larger space for the month, would also be helpful to assemble this frame and attach the canvas.

The wooden stretcher frame will have its advantages, in that it is something I can cut with a jigsaw on my own if I have to. While it will be heavier than aluminum and have a shorter life span, it will get us through the two events this summer. We will also be able to staple the canvas into the wood every few inches underneath, whereas the aluminum version of the frame will require rigging.

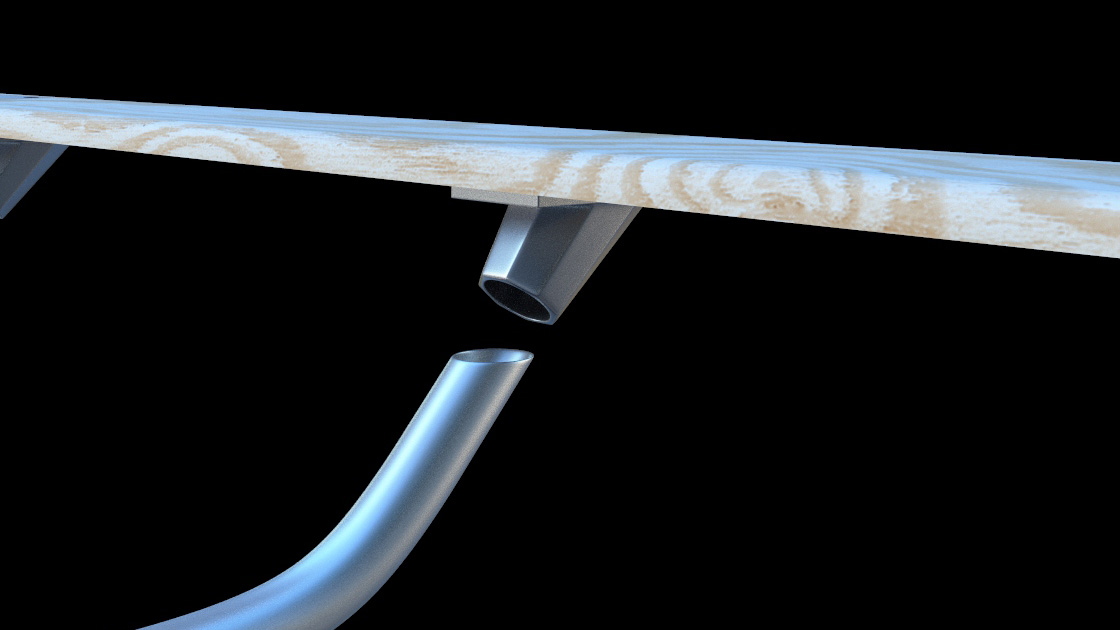

I will still need the help of a metal fabricator to bend the six aluminum ribs but I have found an off-the-shelf flange made to secure railings in order to fix the ribs to the wooden frame.

I am anticipating there will be time to assemble the stretcher frame, although I am feeling the pressure to begin building as soon as possible. I am able to work on the design a little every other night. The majority of my work so far has been in obtaining the permit, which I just received! The insurance is done and the next step is to complete the team to accomplish the event. When we know who is helping, I can submit the list of names for the background checks.

By clarifying this project and the elements involved, I hope to connect to the people who could help with the remaining pieces.